Checkweigher System Benefits And Uses

Checkweigher The Key to Precision Weighing in Industrial Production

Quality control, efficiency and safety are of great importance in industrial production processes. For this reason, every step in the production line must be carried out accurately and precisely. This is where the “check weigher” comes into play. A checkweigher system is an industrial device used to measure and control the correct weight of products. In this article, we will take a closer look at the uses and advantages of the checkweigher system.

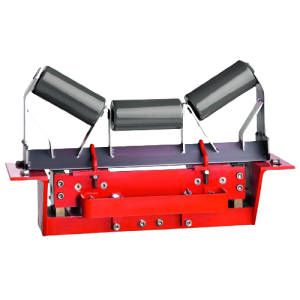

What is Checkweigher System ?

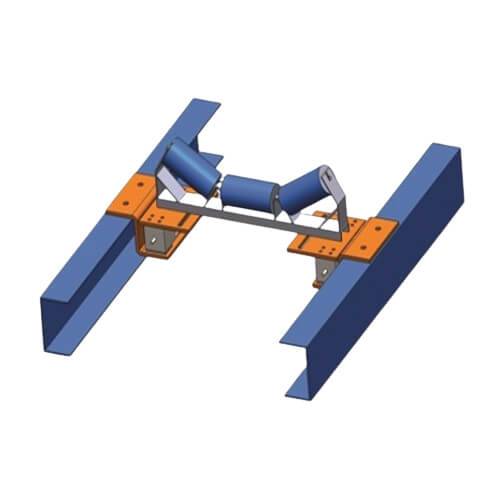

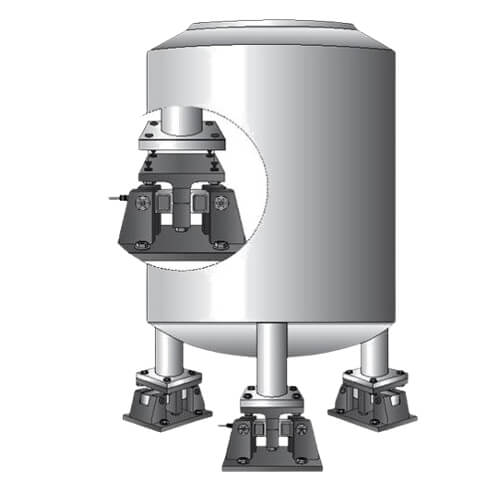

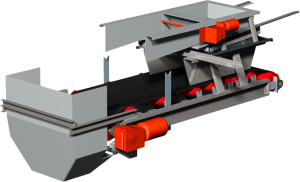

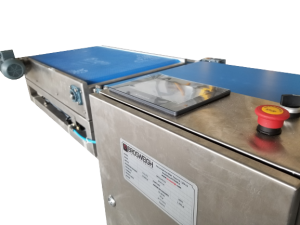

Checkweigher system is an automatic weighing device and is used to measure the correct weight of products in an industrial production line. This device checks whether products are within a certain weight range and rejects faulty products. It can run on a conveyor belt and weighs products continuously. In this way, it is possible to obtain accurate data on the weight of the products.

Checkweigher System Ares of Use

Food Industry: The correct weight of food products is extremely important because the products offered to the consumer must meet standards. It is used to check the correct weight of bakery products, meat products, dairy products, packaged foods and many other food products.

Pharmaceutical Industry: Accurate dosing is vital in pharmaceutical production. It is used to check the correct weight of drug tablets or capsules.

Cosmetics Industry: The packaging of cosmetic products must be correctly weighted. Checkweigher checks the weight of make-up products, perfumes and personal care products.

Automotive Industry: In the production of automobile parts, the checkweigher improves the quality of products and detects defective products by making precise measurements.

Beverage Industry: The correct volume and weight of beverage products is critical for consumer satisfaction. Checkweigher checks the correct weight of beverage packaging.

Benefits of Checkweigher System

In industrial production processes, checking the correct weight and quantity of products is of great importance. Specialized devices such as checkweigher are used both to improve quality and to prevent faulty products from reaching the market. In this article, we will take a closer look at the benefits they bring to businesses.

1. Precise Control and Accuracy

They can measure the weight of products very precisely. This is an excellent tool for checking whether products are within the desired weight range. Having the correct weight of products not only increases customer satisfaction but also prevents the production of low-quality products.

2. Increasing Productivity

Manual weight inspection processes are often slow and error prone. These systems operate automatically and weigh products at high speed. This increases the efficiency of the production line and allows workers to focus on more valuable tasks.

3. Fast Defective Product Detection

They can quickly identify cases where products are faulty. If a product is outside the desired weight range, it is automatically sorted or marked. This prevents faulty products from mixing with other products and reduces recall costs.

4. Improving Quality Control

Improves quality control of products. These devices ensure homogeneity and conformity of products to standards. Thanks to the production of quality products, customer satisfaction increases and brand reputation is protected.

5. Occupational Safety and Health

Manual weight checking operations can require workers to lift heavy weights, which can increase occupational health and safety risks. Check weighers eliminate these risks, allowing workers to work more safely.

6. Data Collection and Analysis

It collects and stores data about measurement results. This data can be used to analyze and improve the production process. They can also be used to generate regulatory compliance reports.

As a result, they play an indispensable role in industrial production processes. They offer a range of benefits such as precise weight control, increasing productivity, detecting defective products, enhancing quality control, ensuring occupational safety and collecting data. These devices help businesses produce more competitive and reliable products and increase customer satisfaction.

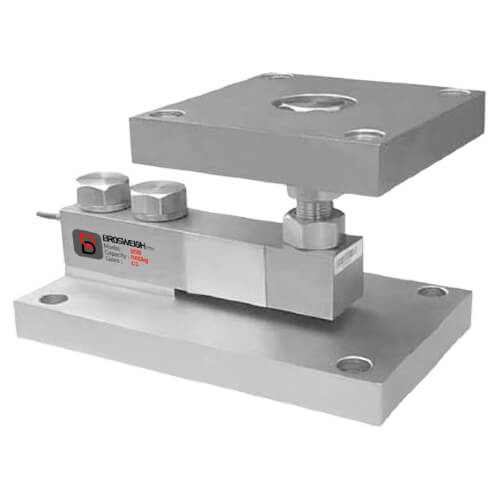

You can click on the link to examine Brosweigh weighing systems checkweigher models. You can click on the link to examine our foreign resources.