What is Checkweigher?

Checkweigher Systems : The Key to Improving Product Quality and Productivity

The manufacturing industry is constantly turning to new technologies and solutions to improve the quality of products and operational efficiency. In this context, checkweighers have attracted a great deal of attention in recent years. By precisely measuring product weight, checkweighers play a critical role in detecting packaging defects and product shortages, increasing quality control and optimizing the production process. In this article, we will discuss what a checkweigher is, how it works and the advantages it provides for businesses.

What is Checkweigher?

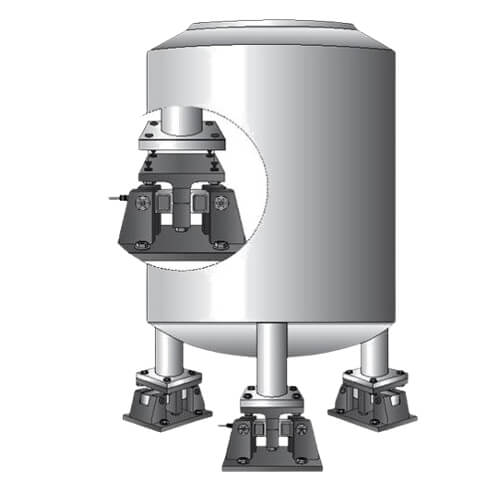

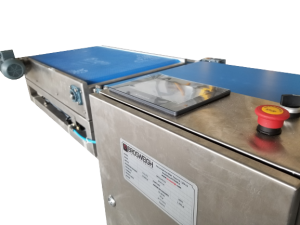

Checkweigher is an industrial equipment used to check the weight of packaged products. It is often used on production lines to ensure that products are packaged at the correct weights and conform to standards. Checkweighers are used in the food, pharmaceutical, cosmetics, automotive and other industries.

Checkweighers measure the weight of a product and compare it to a specific target weight. If the product meets the target weight, the process continues; however, if the product deviates from the target weight, the checkweigher gives a warning or can automatically make corrections. In this way, the quality of the products and the suitability of the packaging are checked.

Checkweighers use a variety of sensors and mechanisms that can operate quickly and precisely on the production line. These devices help to minimize errors and deviations during weight checks. Such devices play an important role in production processes to increase efficiency, reduce waste and ensure product quality.

Working Principle of Checkweigher Systems

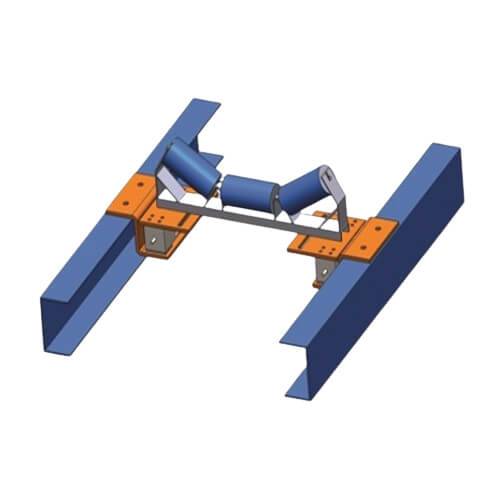

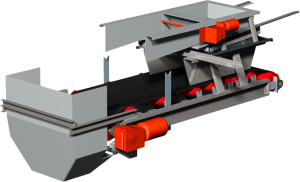

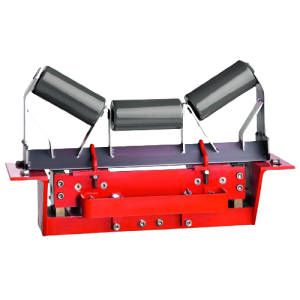

Product Inlet: Products are conveyed to the checkweigher via a conveyor belt or conveying system.

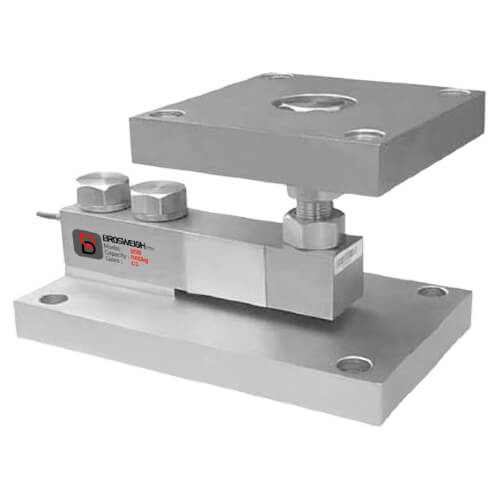

Weighing Process: The checkweigher precisely measures the weight of the products. Meanwhile, the products are automatically placed on the weighing platform.

Data Processing: The measured data is processed by a computer or control system. This system checks for differences between the product weight and certain limits.

Control and Classification: If the product weight is within the specified tolerance limits, the product is accepted and the process continues. However, if the weight is outside the specified limits, the product is rejected or marked.

Advantages of Checkweigher Systems

Quality Control: Checkweighers help detect quality issues such as packaging errors, missing or excess products, which improves product quality.

Speed and Efficiency: Through automation, checkweighers increase process speed and reduce manual operations.

Cost Savings: Early detection of product defects helps reduce recalls and customer complaints, which reduces costs.

Traceability: Checkweighers record and track product weight data, increasing product traceability.

Compliance: Checkweighers can be used to comply with industry regulations and standards, helping your business meet regulatory requirements.

In conclusion, to answer the question what is a checkweigher, it is an important tool in the manufacturing industry to improve product quality and optimize operational efficiency. Early detection of packaging defects and product shortages reduces costs while increasing customer satisfaction. By using checkweighers, businesses can create a more reliable and sustainable production process. Therefore, checkweighers are worth investing in.

In this article, as Brosweigh Weighing Systems, we answered the question of what is checkweigher. You can click on the link to examine the details. You can use the link for foreign sources.