Weighing System and Industry 4.0

Industry 4.0, or the Fourth Industrial Revolution, refers to the integration of automation, data analytics, cloud computing, internet of things (IoT), artificial intelligence and other advanced technologies into industrial processes. They are integrated into industry 4.0 as part of this transformation and this integration offers a number of advantages. Here are some examples that illustrate the role of industry 4.0 in weighing systems.

What is Industry 4.0?

ndustry 4.0, or the Fourth Industrial Revolution, refers to a transformation in which production processes and industrial automation are radically changing. The term is the result of combining traditional production methods with digital technology and automation

The Role of Industry 4.0 in Weigher Systems

Smart Data Collection and Communication

Automation and Collaboration:

Predictive Maintenance

Data Analysis and Optimization:

Personalization and Flexibility:

Security and Monitoring

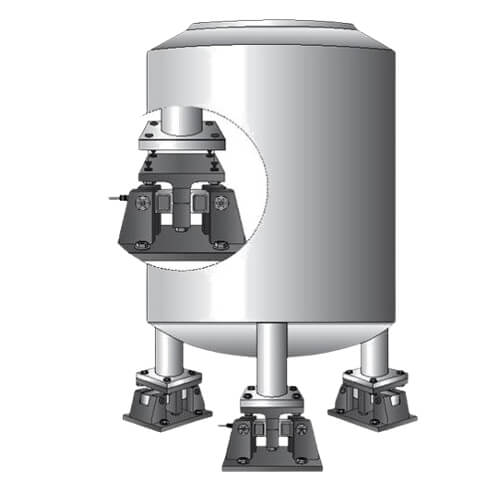

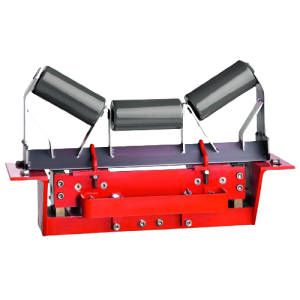

Smart Data Collection and Communication: By adopting Industry 4.0 principles, it can collect and transmit data digitally. This enables key measurements such as product weight and quantity to be automatically recorded and processed. Thanks to IoT, weighing systems make this data traceable and analyzable from a central location.

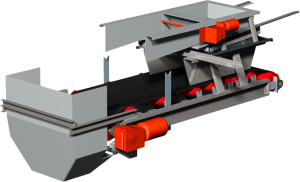

Automation and Collaboration: Industry 4.0 encourages different production equipment to communicate and collaborate with each other. Weighing systems can automatically integrate with other production equipment, making the processes of weighing and packaging products more efficient.

Predictive Maintenance: Industry 4.0 enables predictive maintenance using the Internet of Things (IoT) and artificial intelligence. For example, a weighing system can automatically generate maintenance requests when it detects overloads or problems.

Data Analytics and Optimization: With Industry 4.0, it becomes easier to analyze data from weighing systems and optimize processes. This provides businesses with useful insights to improve product quality, reduce waste and lower costs.

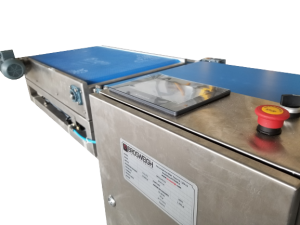

Personalization and Flexibility: Industry 4.0 allows for greater personalization of products and more flexible production processes. Weighing systems can automatically adjust the measuring and labeling of different products, increasing the ability to better respond to customer demands.

Safety and Tracking: With Industry 4.0, weighing systems offer more possibilities to improve product safety and monitor the supply chain. Accurate weighing and tracking of each individual product is vital when a quick recall is required.

Integrating weighing systems into industry 4.0 provides businesses with a more efficient, competitive and sustainable production process. These systems play an important role in data collection, analysis and process control, helping businesses adopt smarter and more flexible production methods.

As a result, Industry 4.0 enables weighing systems to become more intelligent, efficient and competitive. By adopting this technological transformation, businesses can improve their production processes, reduce waste and better respond to customer demands.

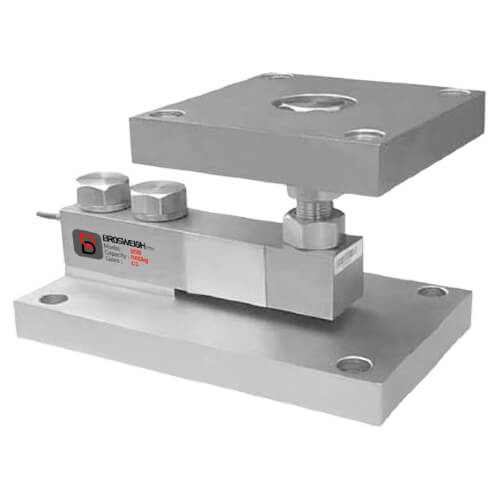

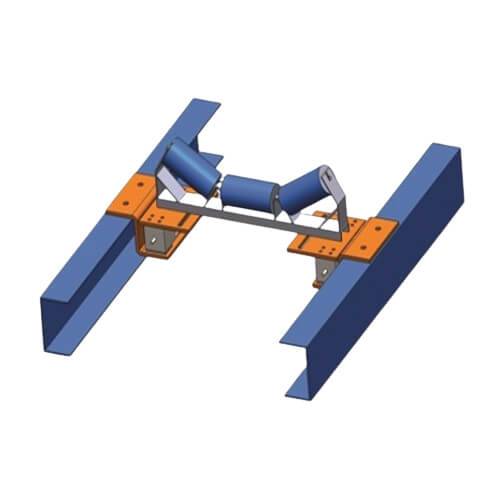

You can reach our website where you can access the products and services offered by Brosweigh Weighing Systems with this link. You can click on the link to examine our foreign resources.